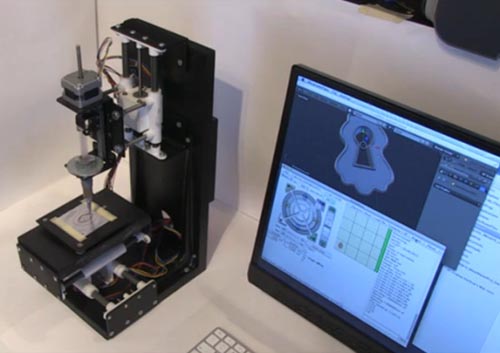

MYSORE: A group of seven engineering students from National Institute of Engineering-Information Technology (NIE-IT) and Vidya Vardhaka College of Engineering (VVCE) have developed a low-cost 3D printer.

Nikhil Furtado, one of the group members from VVCE, said that he was inspired by many reports on the internet, especially the one about the recovery of a woman’s skull. “But its cost was high. So we decided to develop a device at low cost, for which we had to do away with the mould. Our device, developed in August last year, cost us Rs 40,000, while the other 3D printers cost Rs 1 lakh,” he claimed.

Chethan M Rao of NIE-IT, who designed the electronics part, said: “If the 3D printer is used everyday, the mould would cost approximately Rs 1,00,000. So we developed this machine without mould.”

“The machine is used for prototyping and can find applications in architecture, construction, industrial design, automotive, aerospace, military, engineering, civil engineering, dental and medical fields, fashion, footwear and jewellery, eyewear, education, geographic information systems, food and human tissue replacement,” he added.

“We have removed the L-joint as it would prolong the process. We have used metal, concrete, different types of plastics like SLS plastics. The task of designing, assembling and interfacing of electronic components was crucial,” he stated.

“Maintaining the heat of the bed for molten material uniform and the functioning of electronic components as per our design requirements were challenging. It took about three months to develop this technology. In future, we want to reduce the thickness of layers so as to give it a good finish. We also want to increase its size…” he stated.

NIE-IT principal C Vidya Raj said the technology, being cost-effective, helps even the common man.