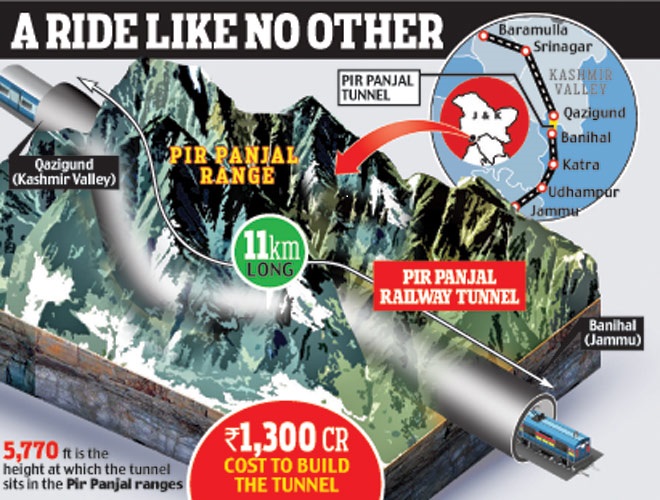

Finishing touches are being given to India’s longest railway transportation tunnel, Pir Panjal Railway Tunnel, which will link Kashmir valley with Banihal tehsil of Jammu.

The 10.96 km is likely to be thrown open this month.

The tunnel connects Bichleri Valley of Banihal with Qazigund area of Kashmir Valley, is the India’s first longest transport tunnel and Asia’s second longest tunnel. Longest tunnel in Asia is Wushaoling tunnel (20 km) in Gansu, China.

The tunnel will reduce distance between Banihal and Qazigund, which is also one of the most treacherous stretches in the entireRs.11,000 crore-worth 292 km Udhampur-Kashmir rail network project, from 35 km by road to 17.5 km on train.

Since October 2009, the railway line from Qazigund to Baramulla (119 km) is operational for public. Now with completion of the tunnel train would run from Baramulla to Banihal.

“This state-of-the-art tunnel is 100 per cent water-proof and equipped with a fire fighting system throughout its entire length,” says Project Manager of Hindustan Construction Co Ltd Sharnappa Yalal.

Yalal has been part of the project since 2005 when it was awarded to the HCC.

“You see we have completed everything. The tunnel can be commissioned any time now,” relieved Yalal said.

The Pir Panjal tunnel is 440 m lower than the existing Jawahar road tunnel so as to ensure that the effect of snow is minimal.

The Jawahar tunnel was built in 1950s by the drill and blast method. While as New Austrian Tunneling Method (NATM) has been employed for the first time in India for Pir Panjal tunnel.

In this method, geological stress from the surrounding rock is used to stabilise the tunnel hole and finishing of the tunnel is carried out simultaneously as one goes on excavating.

The Pir Panjal tunnel has a maximum overburden (height of mountain strata above the tunnel) of 1100 meters.

Yalal said the construction of the tunnel was not an easy task to execute.

“The engineers faced excavation challenges,” he said.

He said the variations in geological terrain conditions within the tunnel had made the excavation work difficult endeavour.

The strata of rock along the tunnel alignment differed from hard rock to soft grounds, forcing the engineers to use different types of excavation techniques like excavation by tunnel excavator or through a road header or by drill and blast method.

The work on this tunnel was started in early 2006 and was scheduled to complete by mid-2009.

“During the course of work, additional work was allocated by to us and thus the tenure of the project was increased simultaneously,” says Vikram Tanwer, Manager Corporate Communications, Hindustan Construction Company Ltd.

“There really was no delay as such in the completion of the tunnel,” he said.

The total cost of the tunnel was Rs. 1300 crore. The officials say there was zero fatality during the entire project.

Tanwer says the tunnel is marvel in tunneling technology and would help in similar other experiments in the region including Ladakh in long way.

Eight different types of geological strata were found across the entire length of the tunnel.

“In some locations, the rock would burst unexpectedly during excavation. Then, there were areas where significant water seepage was encountered from the rock. In spite of all the unanticipated challenges and varying circumstances, the successful execution of this project in testing Himalayan terrain conditions definitely serves as a model for the construction of further such tunnels in this region,” he said.

Engineers also say that some natural streams in the area have dried up due to the cutting of mountain. Locals also said that excavation material, equivalent to two mountains, was not properly dumped and was scattered around.